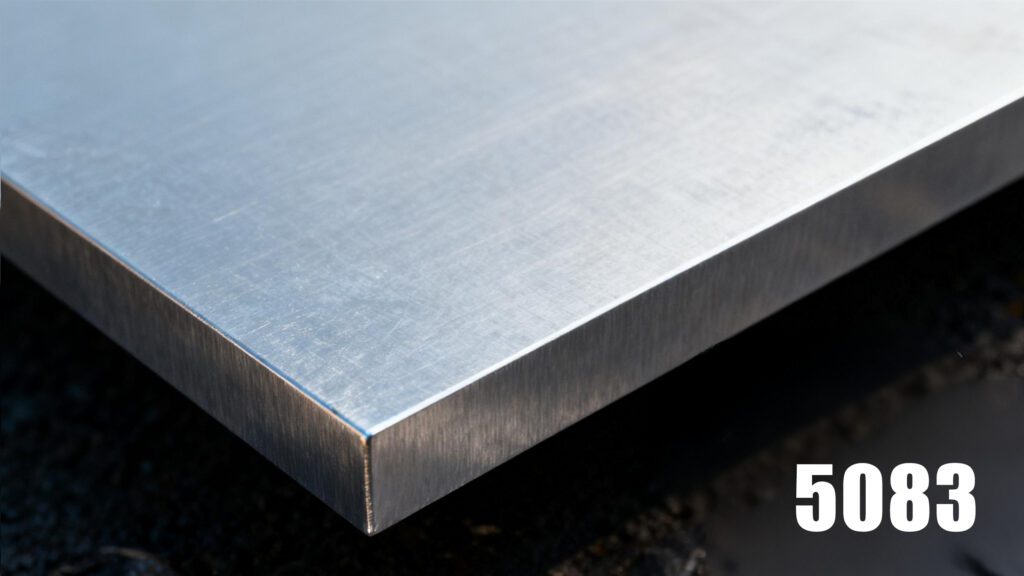

Why Is 5083 Aluminum Plate So Versatile for Marine, Transportation and Multiple Scenarios?

Hot keword :2024 5052 5083 6061 7075

The latest article

- Why Is 6061 Aluminum Rod the Most Versatile Choice for Industrial Manufacturing?

- 5A05 vs 5A06 Aluminum Rods: Choose the Right One for Your Corrosion-Resistant Needs

- For Extreme-Duty Scenarios: 5083 Aluminum Rods—The Unsung Hero of Harsh Environments

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

Why Is 5083 Aluminum Plate So Versatile for Marine, Transportation and Multiple Scenarios?

In harsh fields like marine engineering, transportation, energy, and construction, 5083 aluminum plate has firmly established itself as a preferred choice due to its balanced performance. It can resist seawater corrosion, withstand extreme low temperatures, and meet the demands for lightweight design and high-load-bearing capacity. Its core advantages stem from scientific composition ratio and precise performance engineering.

I. Core Performance: The Key to Multi-Scenario Adaptability

Centered on a high magnesium content of 4.0%-4.9%, 5083 aluminum plate is supplemented with manganese and chromium to optimize its performance, with strictly controlled impurity levels. It boasts a tensile strength of 260 – 385 MPa and maintains stable toughness at -196°C. It is resistant to corrosion from seawater and acid-alkaline media. Additionally, it is easy to process and weld, with weld strength close to that of the base metal. With a density of only 2.66 g/cm³, it holds remarkable lightweight advantages.

II. Core Application Scenarios: Precisely Matching Harsh Requirements

Marine Engineering: It is applied in hulls, decks, and offshore platforms, and has obtained certifications from classification societies such as CCS and DNV. It can replace steel to reduce weight by 30%-40%, while resisting wave impact and seawater corrosion effectively.

Transportation: It is suitable for battery trays of new energy vehicles and body skins of rail transit vehicles. It helps reduce weight and improve efficiency, maintaining stable performance across a wide temperature range.

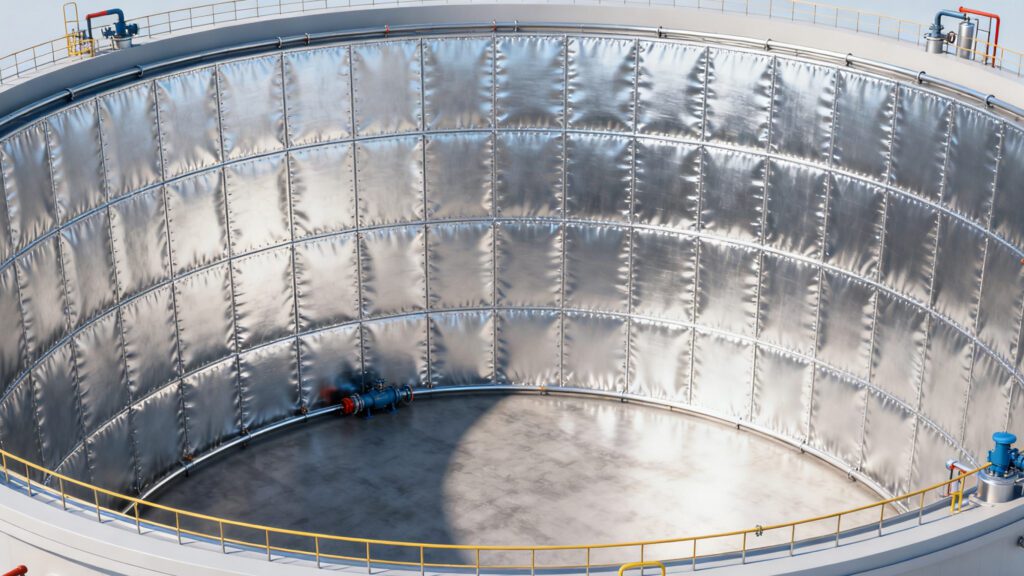

Energy and Chemical Industry: The H321 temper is the top choice for LNG storage tanks, capable of withstanding cryogenic environments. It is also used in chemical storage tanks and pipelines as a substitute for some stainless steel, lowering maintenance costs significantly.

Construction and Infrastructure: It is adopted for curtain walls of coastal buildings and railings of cross-sea bridges. It resists salt spray and UV aging well, and its maintenance cost is over 50% lower than that of steel.

III. Material Selection and Supply: Efficient Adaptation to Needs

1. Quick Guide to Common Tempers

O temper: Suitable for precision formed parts such as automobile fuel tanks.

H116 temper: Tailored for marine scenarios with optimized corrosion resistance.

H321 temper: Core material for low-temperature equipment, ideal for LNG storage tanks.

H112 temper: Preferred for general structural components, balancing strength and processability.

2. Comparison with Other 5-Series Alloys

Compared with 5A06, it has a lower density and cost. While compared with 5754, it offers higher strength. Thus, it is a cost-effective option for scenarios with medium to high performance requirements.

3. Highlights of Supply Services

It is available in stock with thickness ranging from 0.15 mm to 600 mm, supporting custom cutting and surface treatment. Complying with ASTM and GB standards, it can be provided with classification society certifications and material certificates. One-stop post-processing services are also offered to respond to order requirements promptly.

IV. Brief Overview of Typical Cases

Shipbuilding: A container ship using this material for its hull has served for 8 years without corrosion, with fuel efficiency improved by 12%.

New Energy Vehicles: The battery tray made of this plate is 45% lighter than that of steel, leading to a notable increase in driving range.

LNG Storage Tanks: The inner wall of a 160,000-cubic-meter LNG storage tank is made of this plate. No cracks were found in the welds at -196°C, and its service life is expected to exceed 40 years.